Brick industry is fundamental for the development of a country. Whether concerning the manufacturing and processing of bricks, tiles or clay articles, operating conditions may be very hard. Dust, temperature and process complexity may put machineries in heavy-duty work conditions.

Induced Draft Fans. Brick making process requires industrial fans and blowers for exhaust gas treatment plants. After the gas has been draught out thanks to an induced draft fan, a proper abatement plant is necessary to clean furnace fumes before the emission in the atmosphere. The kind of fumes and gas may vary according to the process and different kilns may have different atmospheres too. It may be a typical employ with bag filters, electrostatic precipitators and chimney (smoke outlet).

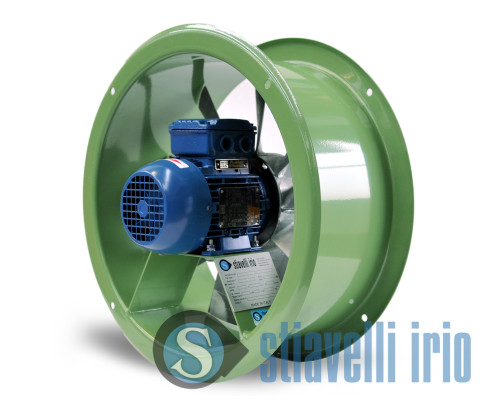

Forced Draft Fans. Not only induced draft fans, but a wide range of fans and blowers specific to supply combustion air to the furnace’s kiln. They are employed for the combustion process and they handle room-temperature air from the atmosphere, creating a positive pressure for the burners. It is right for tunnel kilns and shuttle kilns applications.

Drying and Other Processes. Industrial fans for low pressure air flow with high energy efficiency, suitable for the regulation of the product humidity level to guarantee the perfect desiccation. Applications on rapid dryers, continuous dryers, static dryers. For this process industrial fans direct air on the manufactured products to obtain uniformity of the drying process. Exhaust fans remove the excess of humidity in the dryer system.

Another potential employ is for pneumatic conveying and mechanical draught of mixed powders, minerals and dust.

Reliability and resistance are basic requirements for the fans used in this sector, given the continuity of the production cycles. Likewise, electric motors are in turn subject to intense functioning and must offer the utmost guarantee of duration over time, since the plants are often situated in remote locations and hard to reach.

Efficiency

Compliance with ERP 2015 Directive 2009/125/EC for setting of Ecodesign Requirements for Energy Related Products.

Materials

Standard: Carbon Steel S 235 JR. Upgraded to Stainless Steel AISI 304, AISI 316, or the most suitable material or alloy for the application.

High Temperature

Industrial fans structured for high temperature fluid. Specific arrangements, Cooling Devices and options. Heat Insulation.