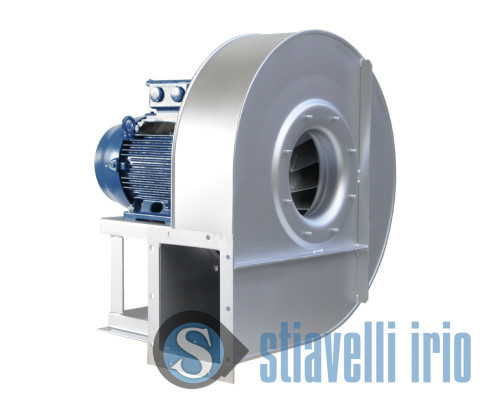

Industrial Multipurpose Radial Flow Centrifugal Fans & Blowers

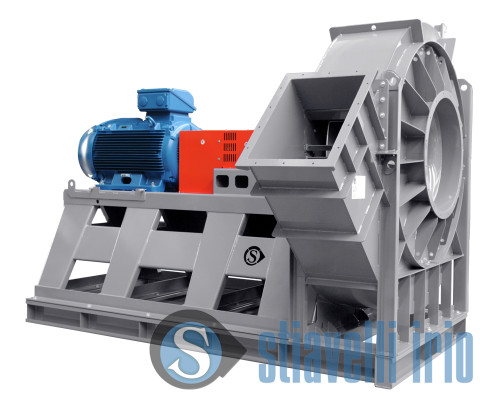

Powered by genuine top quality WEG Motors and Drives

Best Application Fulfillment

Innovative high-grade solutions for the world of fans and blowers. Unparalleled efficiency levels for interrupted or continuous duty.

Dependable Fans and Blowers

Reliability and resistance for strenuous applications. Heavy duty and longlife construction features. Lower maintenance costs and no downtime.

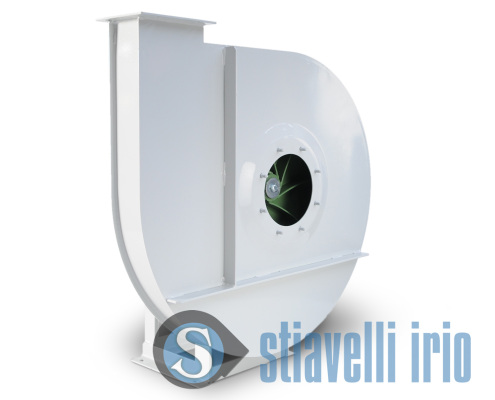

Ergonomic Space-Saving Fans

Rugged advanced design and customized solutions for virtually any kind of existing application. Compact structure for reduced overall dimensions.