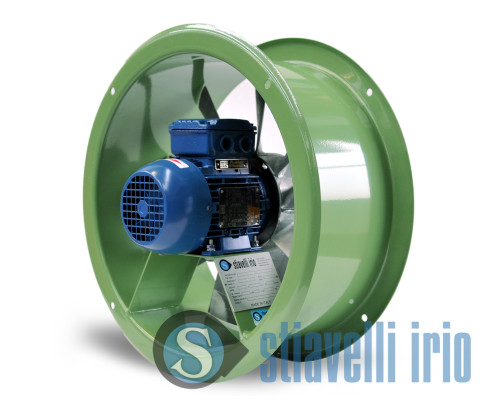

The production of petroleum and natural gas derivatives has seen an exponential growth throughout modern society. These advanced technologies find applications in many aspects of daily life. Industrial fans, blowers and electric motors have an interesting role in treatment processes for oil and gas request safer procedures and high performance to produce high quality products.

Oil and gas industry requires accurate design fans and blowers with welded flanges and components to ensure reliability, resistance and long life in the harshest environments and severe conditions. Extreme temperatures, corrosive atmospheres and request for compact size need advanced technology design and construction know-how. Painting and coating processes are very important. Specific coating process and controls may be adopted on request.

Cooling fans. Industrial fans are widely used with air-cooled heat exchangers for process temperature control. They are an efficient solution to reduce water temperature in chemical and petrochemical industries. Fin fan is a specific heat exchanger system where air pass through a finned tube to dissipate heat generated during the process. Cooling tower fans are the proper solution to dissipate heat into the atmosphere.

Explosion-Proof

Stiavelli Irio Industrial Fans and Blowers may be supplied in explosion-proof version in compliance with ATEX Directive 2014/34/EU.

Materials

Standard: Carbon Steel S 235 JR. Upgraded to Stainless Steel AISI 304, AISI 316, or the most suitable material or alloy for the application. Plastic too.

Efficiency

Compliance with ERP 2015 Directive 2009/125/EC for setting of Ecodesign Requirements for Energy Related Products.