Simple or Heavy Duty, Heat and Corrosion Resistant, Ex-Proof too

High Efficiency Airfoil Blades Impellers: Unparalleled Performance

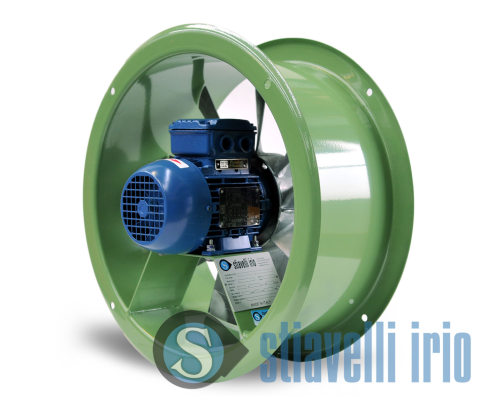

Standard Axial Fans

Compact dimensions and an easy construction set for industrial standard axial fans. A wide range of impellers’ design to fit typical applications with efficiency.

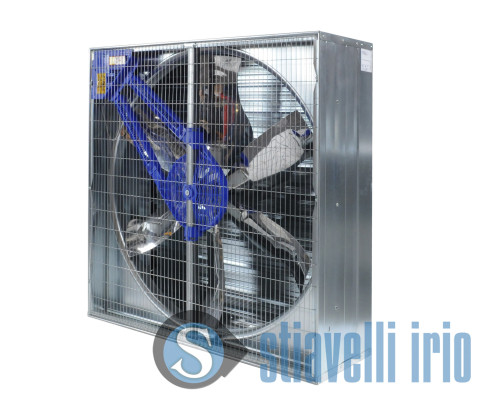

Belt-drive Axial Fans

Belt-drive arrangements to keep the motor outside the flow. Many configurations to customize the fan, optimizing performance, efficiency and noise level.

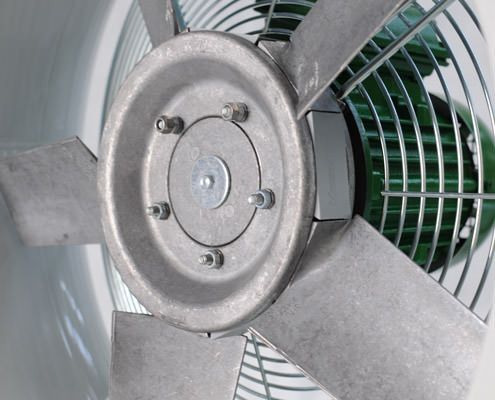

Top-Notch Axial Fans

Reliability and resistance for harsh environments and strenuous applications. Heavy-duty and long life construction set swing-out too.